GFRC & ECC for Commercial Projects

Glass Fibre Reinforced Concrete (GFRC) and Engineered Cementitious Composite (ECC) deliver advanced performance, design flexibility, and long-term durability for commercial construction and architectural applications. Engineered for strength and efficiency, these materials are ideal for projects where aesthetics, structural performance, and buildability must work together.

Both GFRC and ECC enable thin, lightweight concrete elements in complex shapes and finishes—making them well suited to commercial environments where reduced weight, speed of installation, and design intent are critical.

Design Freedom at Scale

GFRC and ECC allow architects and designers to push beyond the limitations of traditional concrete. Using high-performance premixes, fibres, and pigments, panels, benchtops, cladding, and architectural elements can be fully customised to suit the project brief.

From refined interior surfaces to bold external statements, these materials support consistent outcomes across large commercial installations without sacrificing individuality.

Colour Consistency

Integrally coloured GFRC and ECC provide long-lasting, uniform colour throughout the concrete matrix. Pure iron oxide pigments can be blended into the mix to achieve everything from deep architectural greys and charcoals to lighter, stone-inspired tones.

Because the colour is integral rather than surface-applied, it performs reliably in high-traffic and exposed commercial environments, maintaining its appearance over time.

Surface Textures and Finishes

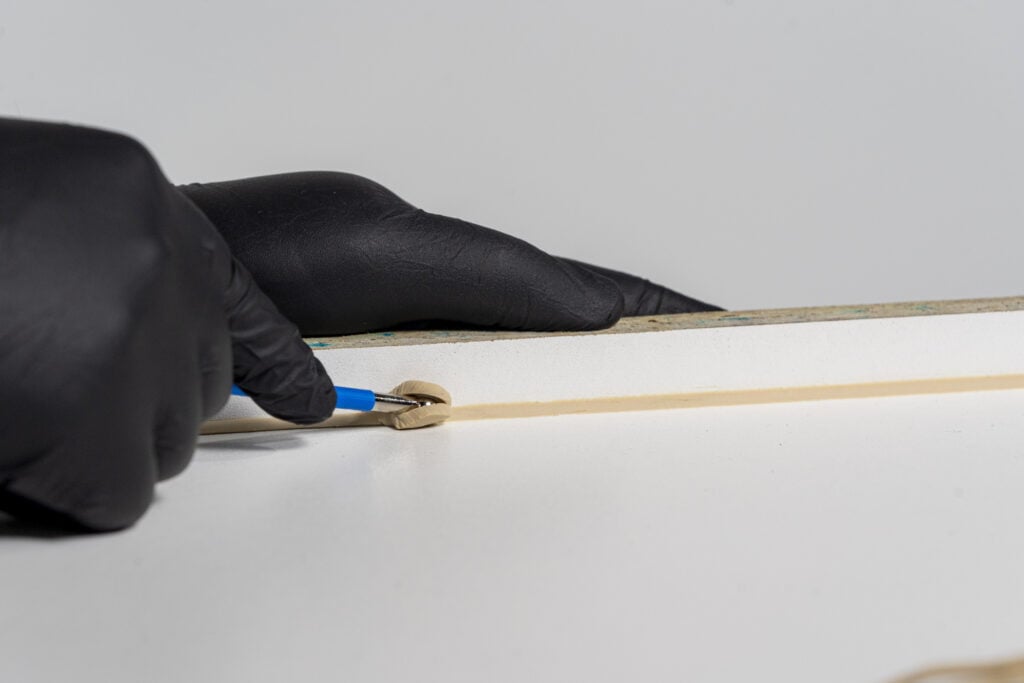

GFRC and ECC can be cast, pressed, or moulded to achieve a wide range of finishes. Smooth architectural surfaces, form-lined textures, patterned moulds, or custom imprints can all be achieved with precision.

This versatility allows concrete elements to integrate seamlessly with materials commonly used in commercial spaces such as glass, steel, timber, and stone.

Complex Shapes and Integrated Elements

Commercial projects often require bespoke detailing and integrated features. GFRC and ECC support:

Large-format panels and thin sections

Curves, reveals, and sharp architectural edges

Integrated fixtures, rebates, and service penetrations

Cantilevered elements and lightweight assemblies

These systems allow complex geometries to be achieved efficiently, without the mass and reinforcement demands of traditional concrete.

Thin, Lightweight Performance

One of the key advantages of GFRC and ECC is their exceptional strength-to-weight ratio. Typical sections can be produced at 20–30mm thickness while maintaining high flexural and impact resistance.

The reduced weight significantly lowers structural loads, simplifies transport, and accelerates installation—particularly beneficial for multi-storey commercial buildings, façades, and retrofit projects.

Durability for High-Use Environments

GFRC and ECC are designed to perform in demanding commercial conditions. Both offer excellent resistance to moisture, impact, and general wear.

ECC provides additional benefits through its strain-hardening and crack-control properties, allowing micro-cracks rather than structural fractures—enhancing long-term durability and service life.

GFRC & ECC vs Traditional Concrete

Traditional concrete is heavy, reinforcement-intensive, and limited in thin or complex applications. GFRC and ECC offer comparable or superior performance while enabling lighter sections, finer detailing, and greater design control.

For commercial projects where efficiency, appearance, and longevity matter, these advanced cementitious materials provide a clear advantage.

Ideal for Architects, Builders, and Fabricators

GFRC and ECC are well suited to commercial applications including hospitality venues, retail spaces, airports, offices, public buildings, and mixed-use developments. Their ability to combine performance with architectural intent makes them a reliable choice for designers and builders alike.

Fabrication can occur off-site or onsite, reducing construction timeframes and allowing greater control over quality and installation logistics.