Ultra-high everything.

Ultra-high compressive strength.

GFRC absorbs weight while resisting changes in size and shape. For example, it could be the weight of a high-rise building on top of concrete foundation

Ultra-high flexural strength.

GFRC has flexural strength as high as 4000 psi, allowing you to bend, sculpt, and cast thin structures without snapping, cracking, or breaking.

Ultra-high tensile strength.

Tensile Strength refers to the maximum load that a material can support without fracture. When the stress on the material has been removed, the materials returns to its original shape.

Finishes You Can Create With GFRC and ECC

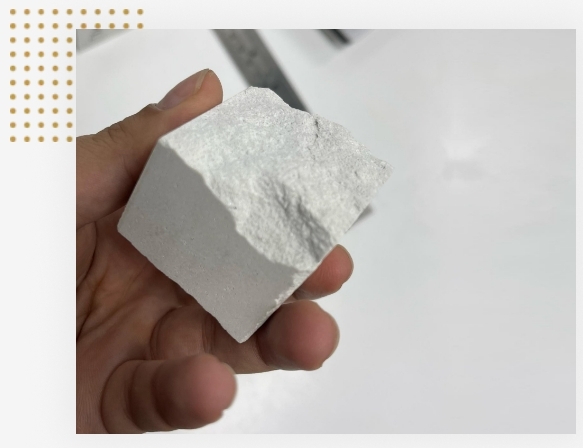

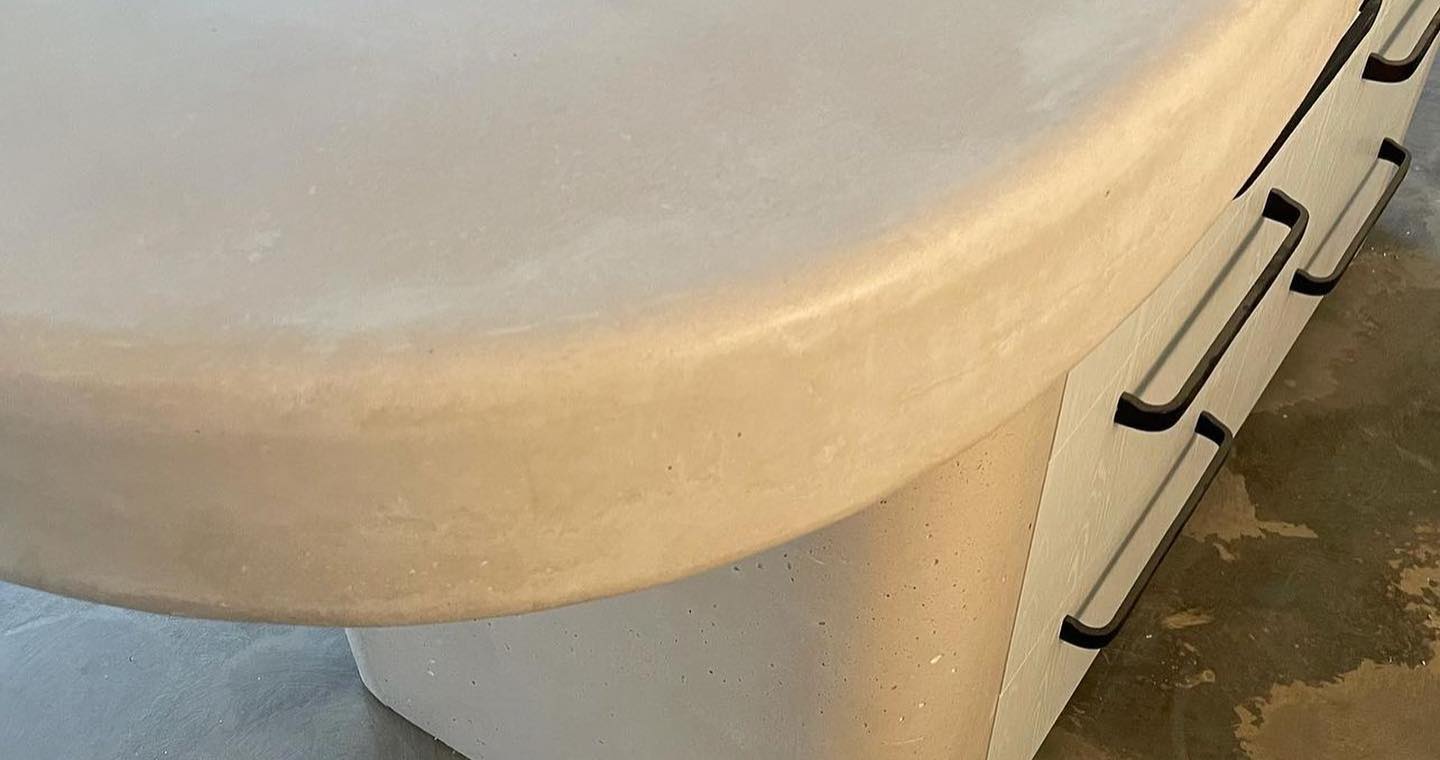

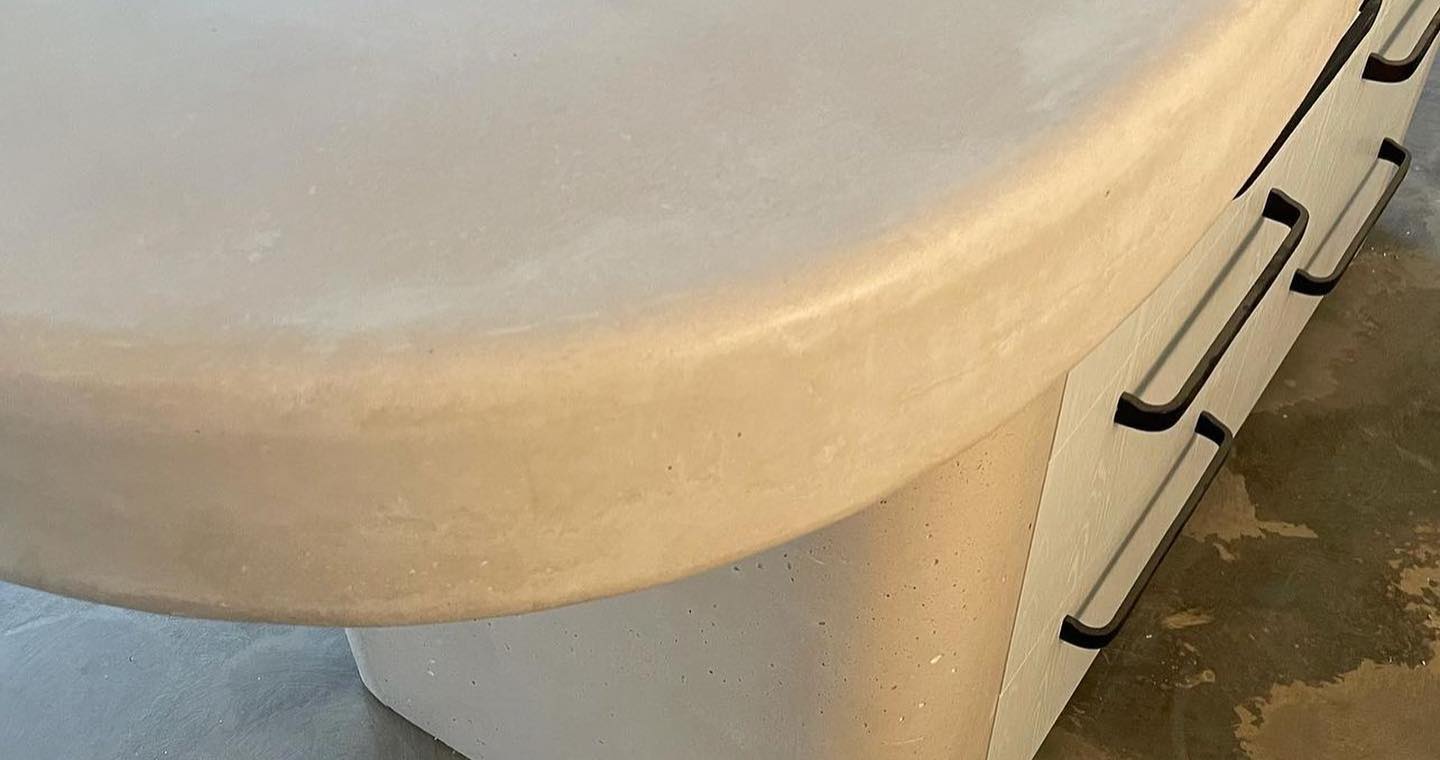

Cream Finish

This finish is accomplished when very little processing is done to a neatly cast piece. It shows loads of character while being soft and muted in appearance.

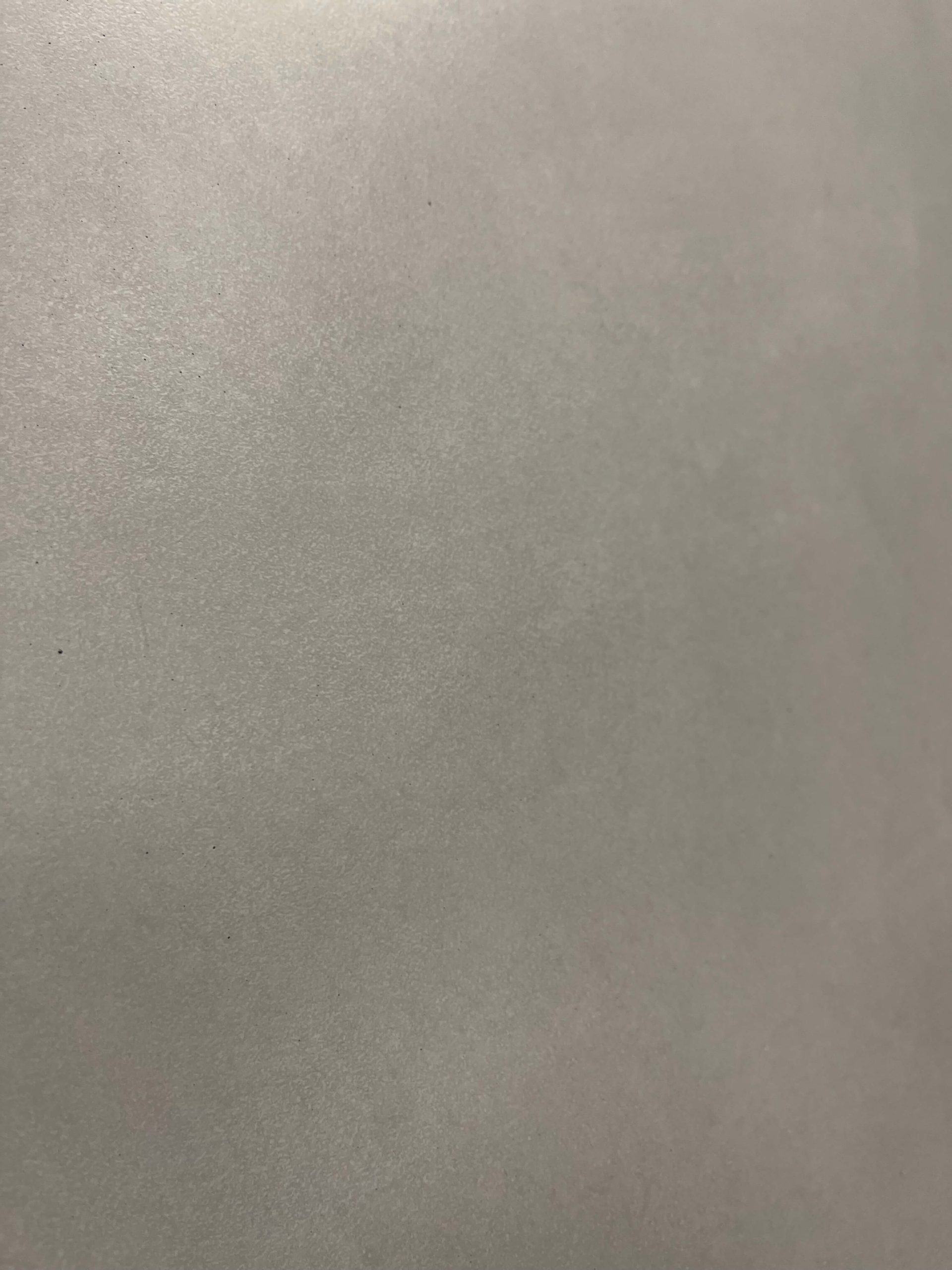

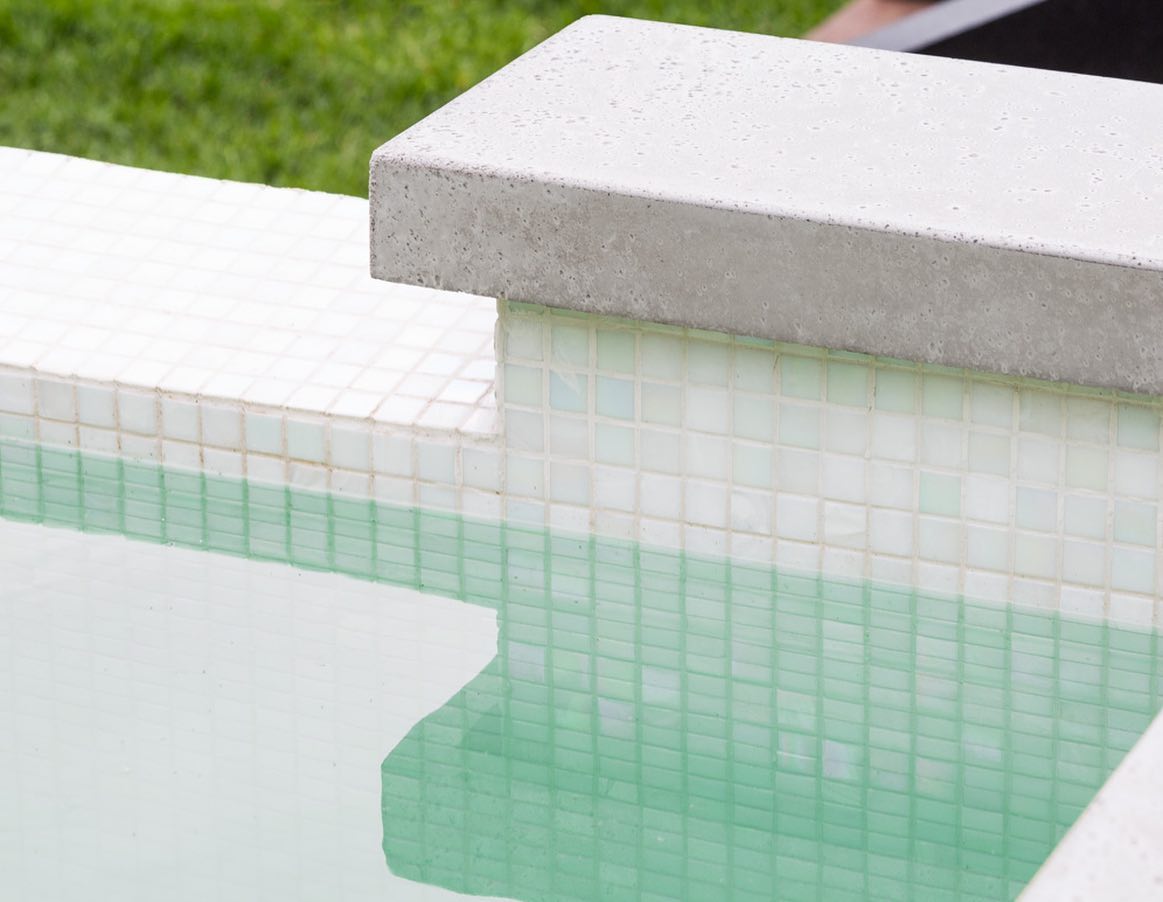

Lightly ground / Salt & Pepper

This finish is commonly referred to as a “salt and pepper” finish. This is a result of polishing the concrete after it has been cast. This process exposes a small amount of sand in the mix.

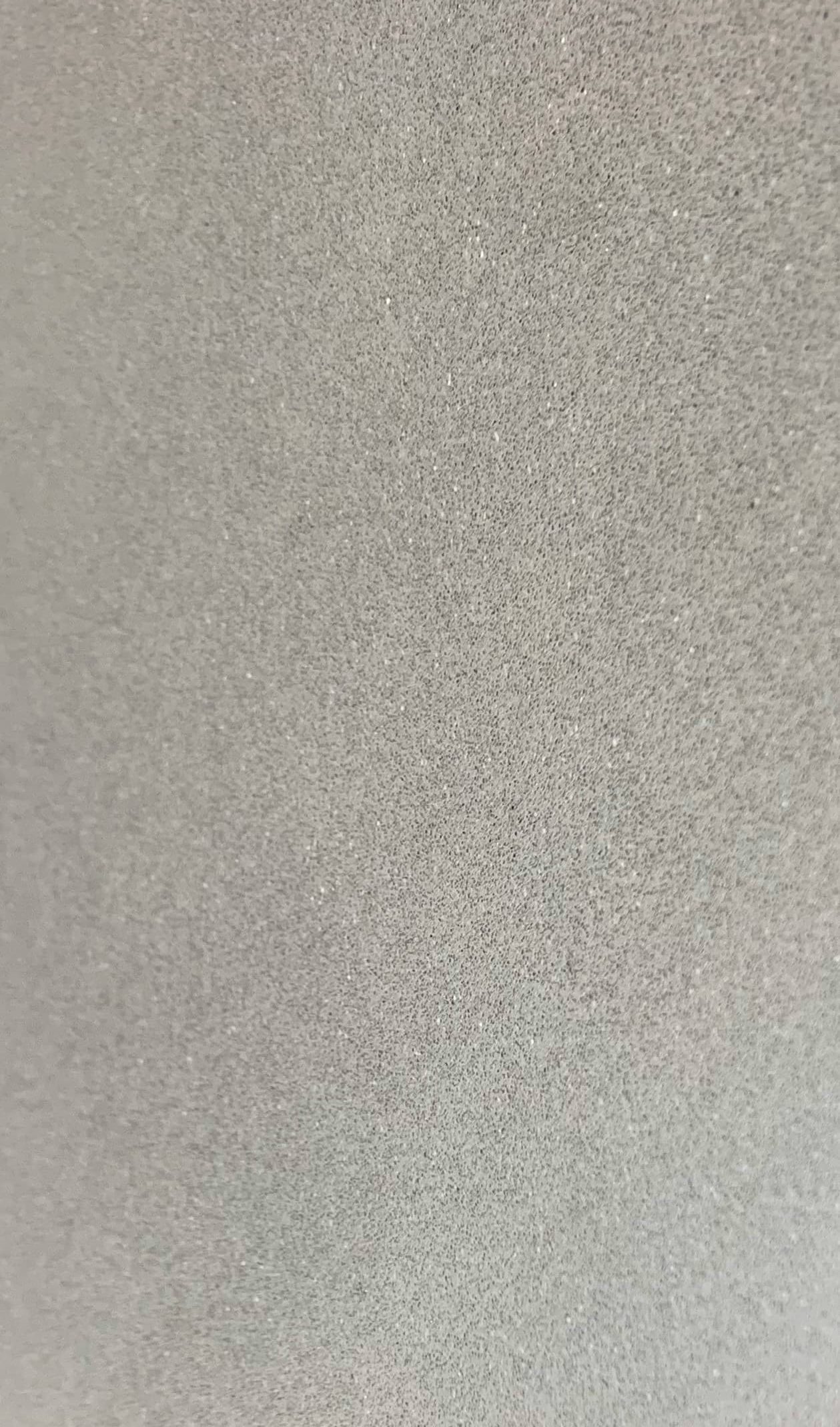

Pressed

The concrete is pressed into forms. The color options are endless. The size of your voids depends on mix consistency and force used to press. This is the easiest finish to get great results from.

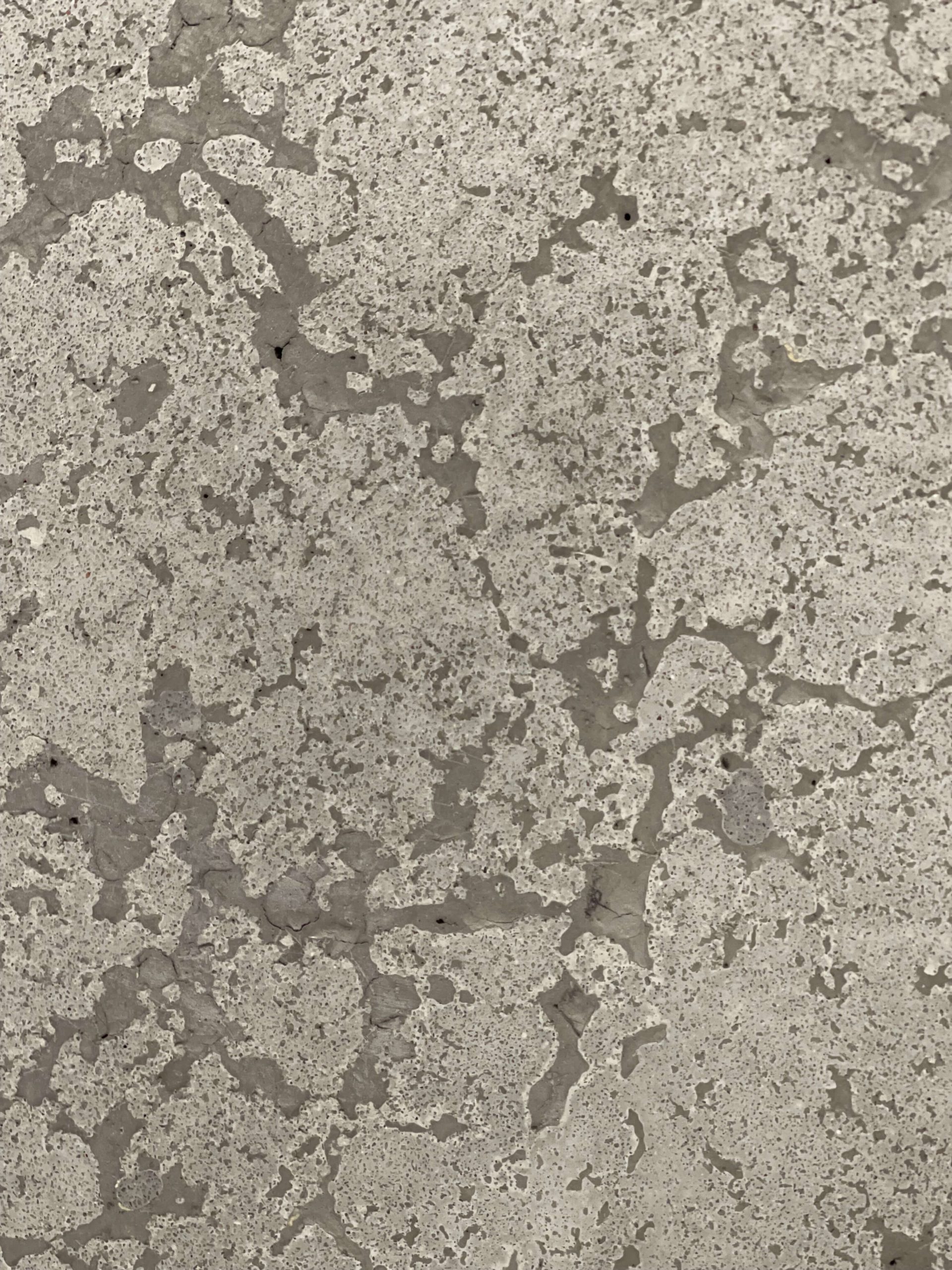

Terazzo / Full Exposure

Similar to Lightly Ground/Salt and Pepper, but more of the surface is removed to expose the sand fully, or to expose decorative aggregates. This is the process to use if you want to expose glass, marble or other decorative aggregates.

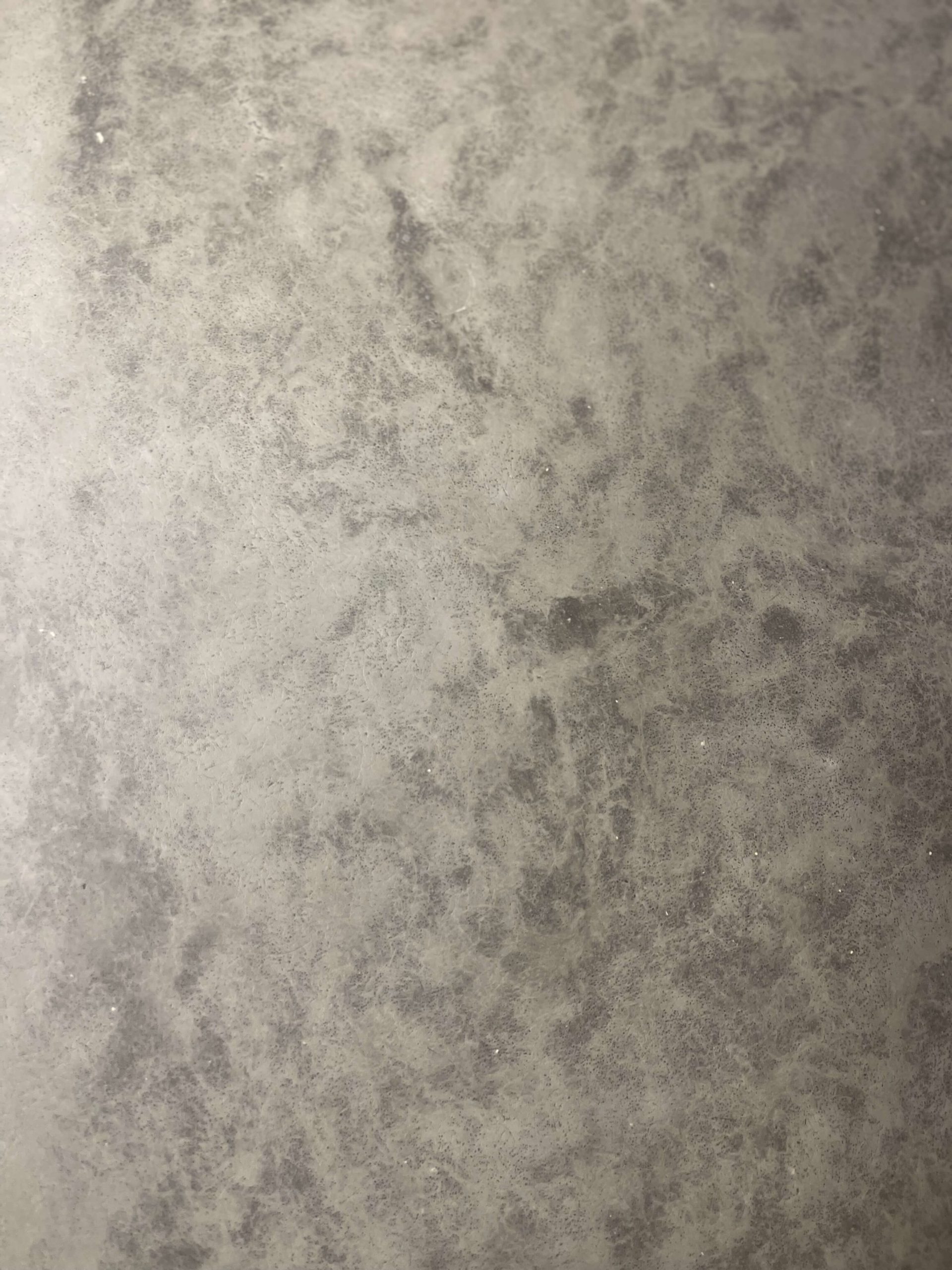

Troweled

“This is a finish that mirrors the talent from the craftsman. Allowing for right-side up insitu castings creating movement and burnishment throughout the surface”

Benefits of GFRC, ECC and

Ultra High Performance

Cementitiouse Mix Designs.

- GFRC is up to 75% lighter than steel-reinforced concrete. You can now create thinner, stronger pieces.

- GFRC comprises of specialised ingredients, engineered for optium partical compaction, resulting in low porosity.

- GFRC additives are white in colour, allowing for customization, through adding iron oxides. This is a incomparable benefit to GFRC manufacturing companies across ANZ

- Crystalline Silica Free*

- GFRC is completely customisable and bespoke, each piece is unique.

- There is no need for joints or expansion joints within GFRC & ECC.

- Due to the particle sizes of GFRC mix design, GFRC can pull an infinite amount of detail, creating texture on the surface. Opening the possibilities for multiple finishes.

- GFRC can be moulded into limitless shapes and sizes, allowing for greater design possibilities

Find a contractor today.

Fire us an email with your project details by filling in the form. We typically respond within 24 hours.

How do glass fibres give

GFRC its super-strength?

Glass Fibre Reinforced Concrete. The glass fibers reinforce the concrete, much as steel reinforcing does in conventional concrete. The glass fiber reinforcement results in a product with much higher flexural and tensile strengths than normal concrete, allowing its use in thin-wall casting applications.

Alkali Resistant (AR) Glass fibers are manufactured from a specialalty formulated glass composition with an optimum level of Zirconia Oxide (ZrO2) to be suitable for use in concrete. These AR fibers are designed to resist breaking down during mixing and processing so that it stays basically as a bundle of filaments.

Products our clients can’t get enough of

What you can make with GFRC.

GFRC’s strength makes it incredibly versatile. It has an array of uses from skyscrapers and high-rise building construction Facades, to exterior claddings and furniture design. It is also lauded in the industry for aesthetic applications such as architectural design, kitchen benchtops, fireplace surrounds, bathroom ware, planters, and more.

Stalk us on Instagram.

Follow @domcrete_gfrc_supplies for inspiration and BTS exclusive content.

TAG @domcrete_gfrc_supplies to feature

Monday to Thursday: 8.30am – 5.00pm Friday: 8.30am – 4.30pm

Monday to Thursday: 8.30am – 5.00pm Friday: 8.30am – 4.30pm